O-rings (O-Ring) are widely used in industries such as hydraulics, pneumatics, construction machinery, aerospace, and electronics. Their primary function is to create seals between components, preventing liquid or gas leakage. O-ring failures may lead to leaks, equipment damage, or safety hazards. Understanding common failure causes and prevention measures is crucial for improving sealing efficiency and extending equipment lifespan.

Failure Symptom: O-rings lose elasticity after prolonged compression, failing to restore original shape.

Causes:

Excessive operating temperatures accelerating rubber aging.

Continuous compressive stress exceeding material’s elastic limit.

Incorrect material selection (e.g., incompatible with medium or temperature).

Prevention:

Use materials with low compression set (e.g., FKM, HNBR).

Maintain 15-30% compression ratio.

Replace O-rings periodically under static compression.

Failure Symptom: O-rings become brittle, cracked, or fragile.

Causes:

Long-term exposure to high temperatures, ozone, or UV.

Material incompatibility (e.g., NBR in high-temperature environments).

Contact with strong oxidizers (acids, alkalis, or cleaners).

Prevention:

Select heat/chemical-resistant materials (e.g., FKM, EPDM).

Avoid ozone/UV exposure during storage/use.

Implement chemical isolation measures.

Failure Symptom: O-rings extrude from grooves, causing edge damage or rupture.

Causes:

Excessive seal gap (>0.15mm).

System pressure exceeding material limits.

Low hardness O-rings (insufficient pressure resistance).

Prevention:

Reduce seal gaps to recommended standards.

Use higher hardness O-rings (≥80 Shore A).

Install backup rings in high-pressure systems.

Failure Symptom: Visible surface wear marks reducing sealing performance.

Causes:

Relative motion between O-rings and metal surfaces.

Insufficient lubrication.

Rough surface finishes.

Prevention:

Use internally lubricated materials.

Select wear-resistant materials (e.g., PU, HNBR).

Optimize surface smoothness and sealing design.

Failure Symptom: Swelling, deformation, or surface erosion.

Causes:

Material-medium incompatibility (e.g., NBR with ketones).

Prolonged exposure to acids, alkalis, or solvents.

High-temperature/pressure accelerating chemical reactions.

Prevention:

Choose chemical-resistant materials (e.g., FKM, FFKM, EPDM).

Conduct compatibility testing.

Apply protective coatings or structural modifications.

Failure Symptom: Size changes due to liquid absorption or solvent evaporation.

Causes:

Material absorption of incompatible fluids.

Plasticizer loss in dry environments.

Environmental fluctuations causing instability.

Prevention:

Use low-absorption materials (e.g., FKM, FFKM, PTFE).

Limit exposure to incompatible media.

Apply pre-treatment or protective layers.

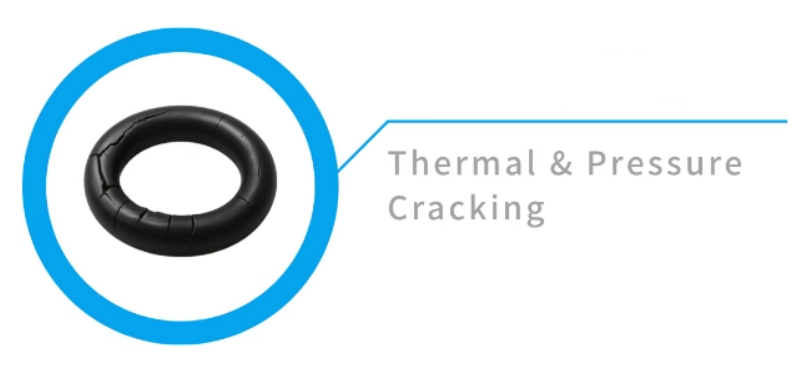

Failure Symptom: Micro-cracks or bursting under extreme conditions.

Causes:

Rapid temperature/pressure fluctuations.

Material limitations (e.g., NBR brittleness at low temperatures).

Prevention:

Use temperature-resistant materials (e.g., FKM, HNBR).

Control pressure change rates.

Ensure stress-free installation.

Failure Symptom: Tears, scratches, or deformation during assembly.

Causes:

Improper tools or overstretching.

Contact with sharp edges.

Incorrect O-ring dimensions.

Prevention:

Use dedicated installation tools and lubricants.

Remove sharp edges from grooves.

Verify O-ring-groove compatibility.

By addressing these 8 failure modes – compression set, hardening, extrusion, wear, corrosion, swelling, thermal shock, and installation errors – equipment reliability and seal longevity can be significantly improved.

For O-ring selection, technical support, or custom solutions, contact Guangzhou Jiarui Seals Co., Ltd. Our experts provide material recommendations, design optimization, and failure analysis tailored to your needs.