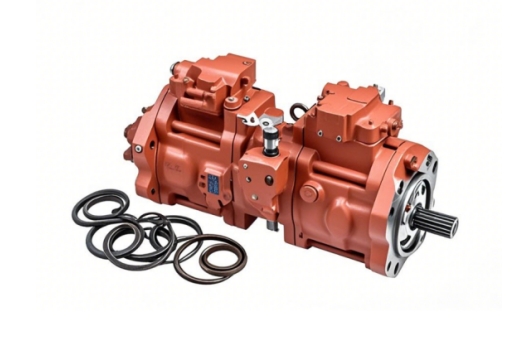

Hydraulic pump leaks are a persistent challenge in excavator maintenance, leading to operational downtime and increased repair costs. As a trusted manufacturer of excavator seal repair kits, Guangzhou Jiarui Seals Co., Ltd. provides actionable insights to address these issues effectively. This guide explores common causes of hydraulic pump leaks and highlights how our specialized seal repair kits deliver reliable solutions.

Hydraulic system leaks fall into two categories:

1. External Leaks: Visible fluid escapes at fixed joints (cylinder bases, pipe connections) or moving parts (piston rods, valve stems).

2. Internal Leaks: Undetected fluid transfer between high/low-pressure zones due to seal failure or pressure imbalances.

Pro Tip: Regular inspections using excavator seal repair kits can identify early signs of wear before leaks escalate.

· Component Imperfections: Even minor deviations in piston dimensions, seal groove depth, or surface roughness (e.g., scratches, dents) compromise seal integrity.

· Improper Installation: Aggressive assembly techniques or misaligned components deform seals. Always use high quality and precision seal parts like Jiarui hydraulic seal kits to ensure precise fitment.

· Inadequate Material Selection: Seals incompatible with hydraulic fluid chemistry or extreme temperatures degrade rapidly. Our excavator seal kits use nitrile, polyurethane, or fluorocarbon materials tailored to your operating conditions.

· Weak Structural Design: Unreinforced joints or undersized components fail under pressure spikes. Custom-engineered solutions from Jiarui Seals enhance system durability.

· Air Ingress: Dissolved air forms destructive bubbles during pressure cycling, eroding metal surfaces. Pair our hydraulic cylinder seal kits with proper deaeration practices.

· Particle Invasion: Dust and metal debris accelerate seal abrasion. Jiarui’s double-lipped dust seals with anti-extrusion rings provide multi-layer protection.

Cracked seals, corroded piston rods, or impact-damaged components require immediate replacement. Our excavator repair kits include all necessary seals, O-rings, and wear bands for comprehensive overhauls.

.png)

1. Precision Engineering: Every seal repair kit undergoes strict ISO-certified quality checks to match OEM specifications.

2. Material Innovation: High-resistance compounds extend seal lifespan by 30% compared to standard alternatives.

3. Custom Solutions: Share your excavator model and operating environment – we’ll optimize seal designs for peak performance.

4. Global Support: Fast shipping and technical guidance ensure minimal downtime.

· Replace seals at the first sign of hardening or surface cracks.

· Use Jiarui’s hydraulic system flush kits during repairs to remove contaminants.

· Install our multi-stage wiper seals to block external debris.

Upgrade Your Excavator’s Reliability Today!

Guangzhou Jiarui Seals Co., Ltd. offers industry-leading excavator seal repair kits designed to eliminate hydraulic leaks and boost productivity. [Contact us] for tailored recommendations or browse our catalog of 500+ compatible seal solutions.