Seal reliability directly impacts equipment efficiency and lifespan. As the professional hydraulic seal kit manufacturer, Guangzhou Jiarui JR Seals analyzes key performance influencers:

Low speed (≤0.03 m/s): Risk of stick-slip ("crawling").

High speed (≥0.8 m/s): Lubricant film breaks down, increasing friction and heat.

Optimal range: 0.3–1.2 m/s for elastomer-plastic composite seals.

Low temperatures: Reduce elasticity, causing leaks and brittleness.

High temperatures: Cause swelling and softness, increasing friction.

Suggested continuous operating temperature range: -10°C to +80°C for composite seals.

Low pressure (<2.5 MPa): Requires low-friction seals.

High pressure: Demands anti-extrusion rings and reinforced grooves.

Note: Composite seals are unsuitable below 2.5 MPa.

The aging or contamination of the oil not only causes the components in the system to malfunction, accelerating the aging and wear of the oil seal, but also the dirt within it may scratch or embed the seal, leading to its failure.

Solution:

Regularly inspect the quality and cleanliness of the oil seal

Timely filter/fluid replacement

System deaeration during startup

Low-pressure pre-operation to remove air

Requirement: Install support rings on pistons for load bearing.

Critical: Seals ≠ load carriers. Use metal rings under heavy loads.

Consequence: Eccentric loading causes leaks and damage.

Causes: Sudden load changes (e.g., excavator hitting rocks), valve switching.

Impact: Instant pressure spikes (up to 4× operating pressure).

Protection:

Buffer rings to absorb shock

Anti-extrusion rings to prevent seal nibbling

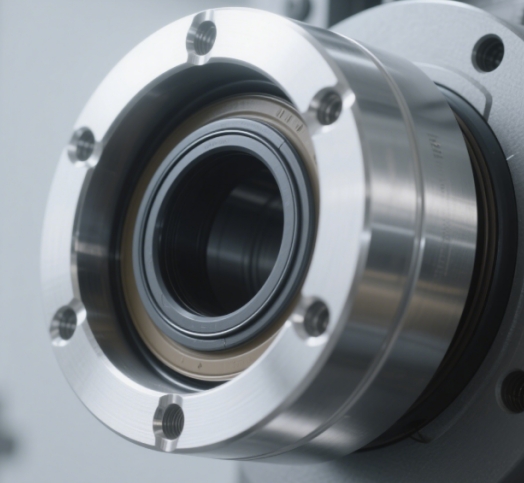

Material: Carbon steel (or aluminum/bronze/stainless steel for low-pressure systems).

Surface: Honed/polished to Ra 0.1–0.8 μm (no longitudinal/cross tool marks).

Material: Chrome-plated carbon steel (or aluminum/bronze/stainless steel).

Surface: Ra 0.2–0.4 μm with hard chrome plating.

Hardness: ≥HRC 60 for abrasion resistance.

Seal groove dimensions

Anti-extrusion gaps

Wear ring clearances

Guangzhou Jiarui Seals Co., Ltd. as the professional hydraulic seal kit manufacturer, offering professional services, standard seal kits and also support customization