Proper installation direction is vital for oil seal performance and equipment reliability. This guide covers essential orientation principles, common errors, and step-by-step installation methods.

The sealing lip (inner lip) must always face the lubricant or sealed medium to prevent leakage.

Examples:

✔ Rotary shaft seals: Lip faces the lubricant side (equipment interior).

✔ Reciprocating seals: Lip faces hydraulic oil/grease side.

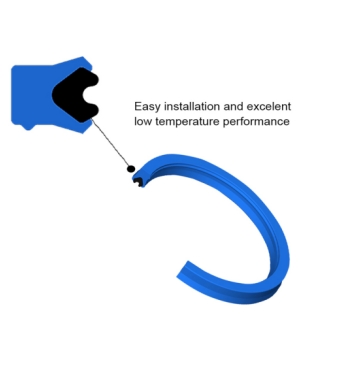

For spring-energized seals, the spring must align with the sealing lip (toward the medium side) to enhance sealing force.

Direction: Lip faces lubricant side.

Application: Single-direction sealing (rotary shafts).

Primary lip: Faces lubricant side (inner).

Secondary lip: Faces outward for dust protection.

⚠ Warning: Reversing primary/secondary lips causes leakage or contamination.

Dust lip: Always faces external environment.

Sealing lip: Faces lubricant side.

Consequence: Lip fails to contact shaft surface, causing leaks.

Example: Installing TC-type primary lip outward.

Consequence: Spring corrosion/breakage from environmental exposure.

Example: Reciprocating seal lip misaligned with piston movement.

Markings Check:

Confirm "IN"/"OUT" labels or directional arrows on seal housing.

Visual Lip Inspection:

Verify primary/secondary lip directions (critical for TC-type).

Spring Position:

Ensure spring aligns with sealing lip (medium side).

Clean Components:

Remove burrs, oil, and debris from shaft/bore.

Apply Lubricant:

Coat sealing lip and shaft with grease to reduce friction.

Use Dedicated Tools:

Press seal evenly into bore using arbor press or guide sleeve.

Post-Installation Check:

Confirm no lip rolling, misalignment, or directional errors.

Align lip direction with rotation to counteract centrifugal forces.

Use double-lip seals with primary lip facing high-pressure side.

Select heat-resistant (e.g., FKM) or chemical-resistant materials while maintaining standard orientation rules.

Need Professionally Engineered Oil Seals and Seal Kits?

Guangzhou Jiarui Seals Co., Ltd. provides:

✅ Direction-specific seals for rotary/reciprocating systems

✅ Custom materials (NBR, FKM, PTFE)

✅ Multiple standard seal kits (support OEM ODM)

✅ Technical support for critical installations